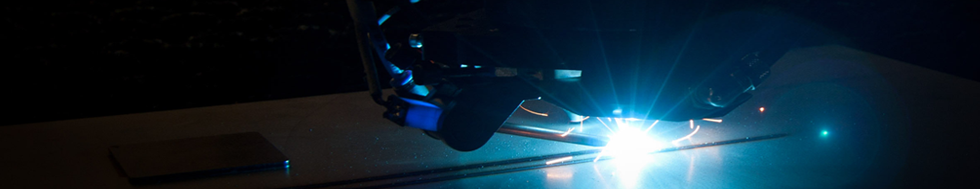

E-Beam Lithography Technology

|

The group of Electron Beam Lithography (EBL) within the Special technology department developed the E-beam lithography technology and Optical diffractive structures.

|

|||

|

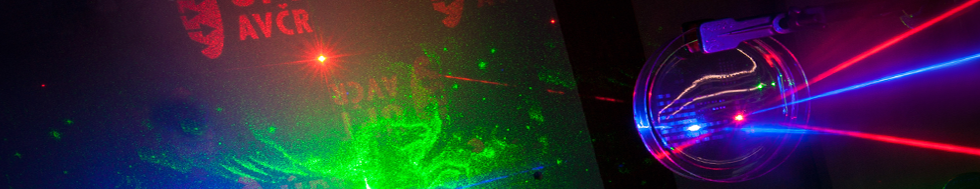

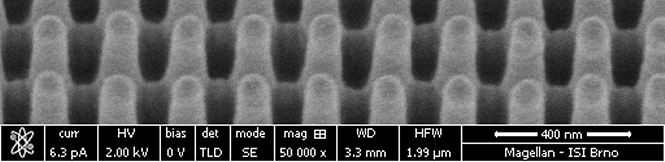

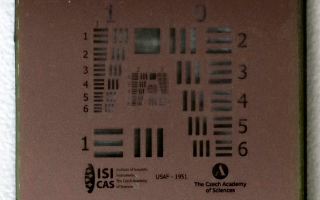

Dimension calibration samples.

|

A required image is enregistered into the thin polymer layer (positive or negative electron resist) by the beam of electrons. The resist-layer mask is created by the development of the exposed patterns. The substrate surface (or the working layer previously deposited on the substrate – either a metallic or a dielectric one) is modified through the resist openings.

Selected R&D result used by industrial partners:

|

The group of Electron Beam Lithography Research areas:

Offered technologies: |

|

Target 1951 USAF.

Target 1951 USAF. Photomask for dynamic measurements of gravity.

Photomask for dynamic measurements of gravity.